PERFORMANCE

Guaranteed for 5 - 15 years

CHEMICAL PROPERTIES

Aqueous fluoropolymer dispersion

PACKAGING

20 litre containers. 1000 litre IBC containers

HEALTH & SAFETY

Non-Toxic, Solvent Free & Water-Based

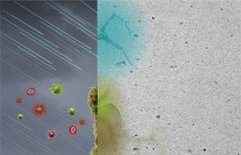

- Epicuro Hydrophobic Bridgeguard® is the leading the EN1504-2 compliant protection product for use on concrete structures. Its unique formula penetrates the concrete's surface to form an invisible (but breathable) barrier that repels water or oily liquids and resists road dirt, graffiti, salts, fuels, vegetation and other surface contaminants.

It also increases the surface's lifespan and reduces the need for costly maintenance and cleaning, making it an ideal solution for large structures such as highway bridges, car parks, airports, coastal structures and other concrete structures.

Untreated Surface Treated with Hydrophobic Bridgeguard

- Hydrophobic BridgeGuard is the leading EN1504-2 compliant concrete protection product for use on all concrete structures.

Featuring 0.0% Volatile Organic Compounds (VOC) it is Epicuro’s flagship product for Responsible Green Engineering.

Hydrophobic BridgeGuard meets the requirements of BD 43/03 Part 2: ‘The Impregnation of Reinforced And Pre-Stressed Concrete Highway Structures Using Hydrophobic Pore-Lining Impregnates’.

Due to its unique formulation, surfaces treated with Hydrophobic BridgeGuard are resistant to oil, road dirt, atmospheric staining and graffiti paints and inks.

Hydrophobic BridgeGuard is a single component, safe to use and environmentally friendly water-borne product (non-toxic, solvent and silicone-free). Tested safe according to 48hr Acute Toxicity Test.

Hydrophobic BridgeGuard is a permanent, colourless, non-film-forming treatment that keeps the surface permeable to air and water vapour. It is UV-resistant and does not discolour with age.

A surface treated with Hydrophobic BridgeGuard will stay cleaner, benefit from an increased lifespan and be easier to maintain. Hydrophobic BridgeGuard prevents deterioration caused by frost attack, acid rain and contaminates such as salts, oils, greases, fuels and graffiti. It also combats the development of moss and vegetation.

Related Epicuro products are HBG for building facades and HBG-HD for pavement. - Tested compliant with EN1504-2/BD43-02

- Unique 0.0 % VOC product

- 15 years manufacturer’s guarantee.

- Prevents freeze-thaw deterioration

- Resists carbonation by surface repellence

- Invisible Anti-Graffiti and Anti-Stain protection.

- Apply to vertical and horizontal surfaces.

- Prevents penetration of water and oily liquids.

- Non film-forming, allows the surface to breathe.

- Water-borne product, non-hazardous & non-toxic

- Solvent and silicone-free.

- 95% + biodegradable according to OECD standards.

- UV-resistant, does not discolour.

- Apply by spray, brush or roller straight from container.

- Non-flammable.

- Physical State at 20°C: Liquid.

- Appearance : Colourless.

- Odour: None.

- pH: 8 ± 0.5

- Boiling point [°C]: 100 °C.

- Density: 1.0 Kg/l

- Solubility in water [vol/vol] : Fully soluble

- Flash Point [°C] : Not applicable.

- Ensure the surface to be treated is clean, dust-free and touch dry before applying the product. Remove all atmospheric pollution-related dirt from all surfaces to be treated before starting the treatment. Jet wash if necessary, but allow the surface to dry completely before application and confirm that the surface has sufficient absorbency (trial area suggested).

- Apply only when the surface temperatures is in the +5o C to +30o C range. Do not apply if rain is expected within 4 hours.

- Use direct from container, shaking well before use. Do not dilute. The treated surface should be impregnated to saturation point. Apply 1-2 coatings uniformly with a brush, roller or low pressure spray equipment, keeping the surface saturated with the product. On vertical surfaces, apply from the bottom up.

- Clean tools and equipment with water immediately after use.

- Drying time: 1-2 hours (subject to ambient temperature). Resistance to water after 6 hours. Full resistance to graffiti & liquids will develop over 5-7 days following application.

- Eye protection: If there is a real risk of splashing wear protective goggles.

- If swallowed: Do not induce vomiting. Contact a doctor or a specialist.

- Respiratory protection: Under normal conditions of use where adequate ventilation is available, no special respiratory protection equipment is needed.

- Hand protection: Wear gloves.

- Skin protection: No special protective clothing or skin protection is required under normal conditions of use.

| The worst case result means for any combination of two batches is as follows: |

Criteria | Mean of 2 batches |

Pass/Fail |

|---|---|---|---|

| Dry rate coefficient | >30% | 68.02 % | Pass |

| Absorption rate | <7.5% | 6.29 % | Pass |

| Absorption rate (after alkali) | <10.0% | 8.49 % | Pass |

The worst case result means for any combination of two batches is as follows:

Dry rate coefficient

Dry rate coefficient

- Criteria: >30%

- Mean of 2 batches: 68.02%

- Pass/Fail: Pass

- Criteria: <7.5%

- Mean of 2 batches: 6.29 %

- Pass/Fail: Pass

- Criteria: <10.0%

- Mean of 2 batches: 8.49 %

- Pass/Fail: Pass

Testing conducted in accordance with: BD43 & EN 1504-2. Copy of full test report available on request.

RELATED CASE STUDIES

Important: The content of this documentation is based on our experience of the product. Epicuro Ltd guarantees the quality of its products, but expressly declines any liability in the event of failure by the user to comply with the

recommendations and conditions of use of said products, notably but not exclusively in the event of incorrect

application, application by unqualified personnel, use of products not compatible with Epicuro’s products or bad weather conditions. For further information, refer to the safety data sheet.

©

2006 - 2024

Epicuro Protective Materials. All Rights Reserved.